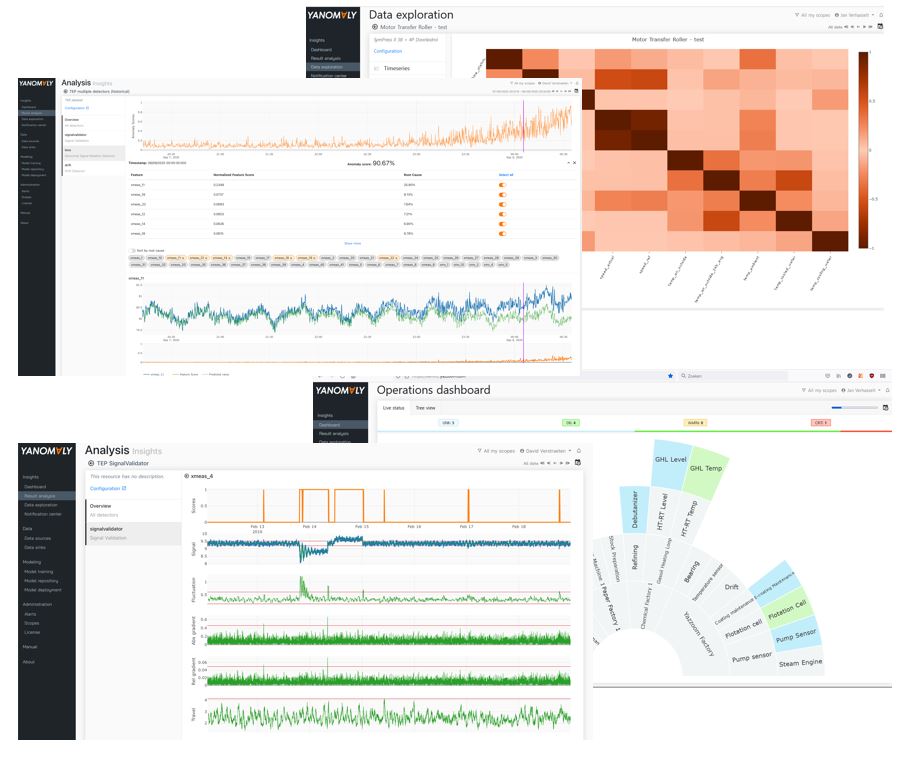

Machines, assembly lines, packaging lines and continuous or batch production processes generate more and more data that is full of hard to extract but valuable information.

YANOMALY is an industrial data analytics software solution that enables you to use that data for:

YANOMALY has a proven track record on a variety of machine and data types: continuous and batch industrial production processes, as well as discrete manufacturing assembly and packaging lines and machines.

YANOMALY is not yet another Industrial IoT platform. Instead, it is a plug-in software that is used to add advanced data analytics capabilities to any existing machine data collection system like data historians, SCADA/DCS or cloud platforms.

Customers of YANOMALY include process and manufacturing production companies, machine builders and IoT platform developers.

YANOMALY is an industrial data analytics software solution that enables you to use that data for:

- Real-time monitoring of the condition of your assets through sensor validation and proprietary AI-powered anomaly detection specifically developed for machine health monitoring

- Implementing and deploying predictive maintenance solutions tuned to your needs by combining the best AI-capabilities and human expertise

- Building, validating an deploying predictive models, for example virtual sensors that predict what the outcome of lab measurements will be

- Giving real-time advice to operators on how to realize golden production runs

YANOMALY has a proven track record on a variety of machine and data types: continuous and batch industrial production processes, as well as discrete manufacturing assembly and packaging lines and machines.

YANOMALY is not yet another Industrial IoT platform. Instead, it is a plug-in software that is used to add advanced data analytics capabilities to any existing machine data collection system like data historians, SCADA/DCS or cloud platforms.

Customers of YANOMALY include process and manufacturing production companies, machine builders and IoT platform developers.

Powerful AI-powered Functionalities

Anomaly detection YANOMALY doesn't need an issue to have already occurred in the past to detect it. It can learn normal behaviour of sensors, control loops, equipment, machines and processes and detect deviations from that normal behaviour.

Read more

It detects unusual combinations of values, patterns and behaviour of sensor signals, and can also pick-up abnormal execution of control software. Our proprietary unsupervised machine learning algorithms can sense any deviation from normal operations, and will also indicate what exactly is abnormal about the machine or process. YANOMALY informs you about the condition of your assets and creates value by speeding up the root-cause finding and fixing of technical issues. For frequently occuring assets like motors, drives, pumps, control loops and valves, Yanomaly has dedicated anomaly detectors that incorporate expert knowledge about equipment issues and how they affect related sensor signals. |

ASSET HEALTH MONITORING

In addition to its generic anomaly detectors that can be applied to anything, YANOMALY also has dedicated asset-specific asset health detectors for often occuring equipment.

Read more

In particular for motors, VSDs, pumps, control-loops, compressors and heat-exhangers. These asset specific detectors combine AI capabilities with built-in human expertise about how to monitor these assets |

Predictive modelsPredictive modeling allows you to build machine-learning models that predict failures (prognostics) or product properties (virtual sensors) and deploy them in production.

Read more

With self-service tools, YANOMALY allows domain experts to build models that anticipate unwanted events such as technical issues, used for predictive maintenance, or quality problems. Typical applications of the latter are virtual sensors that predict the result of lab measurements of product quality characterists. Data pre-processors, predictive models and graphical user interfaces developed specifically for industrial applications are available at your fingertips. |

GOLDEN PRODUCTION RUN ADVISOR

AI-based multivariate centerlining helps you identify the process variables and settings that are most important to realize best possible (or "golden") production runs. Yanomay learns how these variables interact and determines and recommends the best settings and ranges, and this for each product and in different operating conditions. Ensures the process runs with the centertlined settings through visual suggestions, alerts, or if desired even automatic control. |

Setting CHANGE DETECTOR

This self-learning functionality detects changes in machine settings or setpoints and signals any modifications that are unexpected. It can for example alert you when certain variables that are supposed to be changed only during maintenance are modified outside of maintenance operations, or it can help you quickly determine which parameters where modified before a problem occured. |

Main use cases

Operations & MaintenanceReal-time machine health monitoring with early warning of technical issues, prediction of failure for predictive maintenance and better OEE. Continuous improvement thanks to diagnostic analytics. |

Service & SupportFaster diagnostics & root-cause analysis thanks to AI-assisted data exploration, for lower MTTR & more efficient service teams. |

EaSY TO USE INDUSTRIAL PREDICTIVE ANALYTICS, ALSO FOR NON DATA-SCIENTISTs

With self-service tools, YANOMALY allows domain experts to build models that anticipate unwanted events such as technical issues, used for predictive maintenance, or quality problems.

Data pre-processors, predictive models and interface developed specifically for industrial applications are available at your fingertips.

Data pre-processors, predictive models and interface developed specifically for industrial applications are available at your fingertips.

Connect your data, add new capabilities to your existing platform, EDGE or Cloud

Built to be interfaced or integrated with existing data monitoring or IoT platforms, YANOMALY can process all types of data from sensor signals and other time-series data to event and alarm logs of machines, categorical data coming from ERP and MES systems and more.

Thanks to an always expending collection of data connectors, you can easily import information from historians, cloud platforms and data silos, and integrate the results from the monitoring and analytics modules into other systems, with historical and real-time streaming data.

With its modular highly scalable architecture and flexible licensing, including OEM integration, YANOMALY can easily work with existing monitoring platforms, in the cloud or on premise.

Thanks to an always expending collection of data connectors, you can easily import information from historians, cloud platforms and data silos, and integrate the results from the monitoring and analytics modules into other systems, with historical and real-time streaming data.

With its modular highly scalable architecture and flexible licensing, including OEM integration, YANOMALY can easily work with existing monitoring platforms, in the cloud or on premise.

and more...

PROVEN RESULTS THANKS TO PROPRIETARY ALGORITHMS THAT COMBINE MACHINE LEARNING WITH HUMAN EXPERTISE ABOUT SPECIFIC EQUIPMENT

AI and machine learning algorithms specifically developed for analysing industrial and machine data give YANOMALY the edge in performance and results for data analytics and asset monitoring.

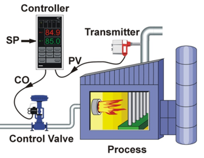

YANOMALY also integrates human expertise-based specialized data analytics for specific applications, such as detecting drift caused by gradual fauling or deterioration, detecting controller or control valve issues, detecting issues with motors and variable speed drives, detecting pump issues etc.

YANOMALY also integrates human expertise-based specialized data analytics for specific applications, such as detecting drift caused by gradual fauling or deterioration, detecting controller or control valve issues, detecting issues with motors and variable speed drives, detecting pump issues etc.

MOTOR + DRIVE MONITORING

|

PUMP + MOTOR MONITORING

|

CONTROL LOOP + VALVE MONITORING

| ||||||||||||||||||

Customer cases examples

AI in manufacturing, what some call manufacturing 4.0, and other industries is becoming increasingly common: Gas turbines for power generation, automated assembly lines in the automotive industry, chemical processes, paper and pulp machinery and more, YANOMALY has been successfully deployed on many different types of assets.

AI-powered Anomaly Detection for Combined Heat and Power plants

|

For its real-time cloud-based data monitoring platform OneBoard, which is also used by its customers, Engie Laborelec wanted to integrate an advanced anomaly detection technology. It had to be self-learning, flexible to configure and simple and efficient enough to be used by its power generation experts without a regular support from data scientists.

Yazzoom’s solution, Yanomaly, was chosen by Engie Laborelec after benchmarking the reliability of the detection of anomalies against competitor solutions. The flexibility of integrating YANOMALY into their existing architecture without the need to switch to another data monitoring platform was another deciding factor. |

Improved OEE of automotive components production lines with ML-based data analytics tools

|

Tenneco produces car components on advanced automated assembly lines. Yazzoom’s software tool YANOMALY is used to detect and diagnose technical deficiencies and throughput bottlenecks in these complex machines that feature multiple-step processes.

By analysing the PLC signals, the tools help Tenneco detect early signs of issues causing low throughput or future failures and to faster diagnose the root cause of performance issues affecting throughput. With better, more detailed, analytics and reporting of the line functioning, data-driven decision-making improves the operations and maintenance of the equipment. This way, Tenneco can ensure higher equipment availability and more consistent asset performance. |

Batch Chemistry Process Monitoring powered by AI

|

To guarantee perfect quality and process safety, Agfa Specialty Products uses monitoring systems for their production units.

As an additional layer of security, on top of human-written rules and alarm systems, they decided to leverage the latest advances in Machine Learning and Artificial Intelligence for anomaly detection by integrating YANOMALY into their monitoring system. YANOMALY was selected after proving it could generate early warning of process issues several weeks in advance compared to the current tools, thus also enabling predictive maintenance. |

PREDICTIVE HEALTH MONITORING OF PAPER MACHINES AND STOCK PREPARATION

|

Since 2020 Yanomaly's anomaly detectors continuously monitor 600 control loops, valves, motors, pumps, drives and other assets in the Stora Enso Langerbrugge plant. It raises alerts when the health of these assets deteriorates and visualizes specific information to speed up the problem diagnosis.

In total 30000 process signals are continously monitored by Yanomaly running on a local server that is connected to the process data historian. |