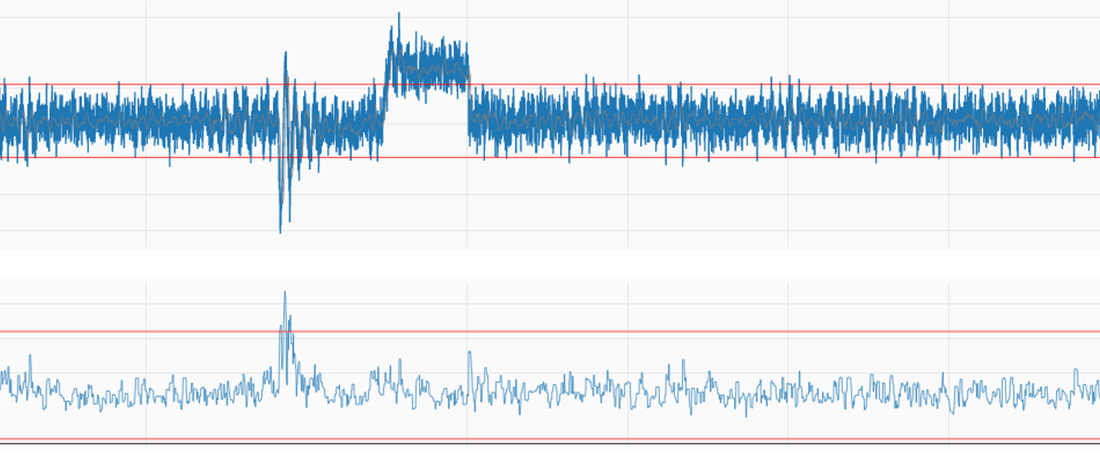

Installations are equipped with hundreds or even thousands of sensors. Yanomaly’s sensor validation automatically learns normal behavior of every individual sensor and reports abnormal ranges, abnormal dynamics, spikes and lost signals, while taking operating condition into account.

Reliable sensor data is a fundament on which many decision processes and controls are based. Undetected sensor issues have very significant impact on:

- Product quality

- Production efficiency & volume

- Safety & Environment risks

- Maintenance effectiveness

Manually checking hundreds of sensors regularly is not economically viable and simple methods like min-max ranges on sensor readings miss many sensor issues.

|

Yanomaly's powerful algorithms analyse process data (from e.g. OPC server or data historian) and learn the normal behaviour of signals thanks to the integrated machine learning (AI) algorithms.

The signal validator learns the normal behavior for each of the different operation conditions automatically. Deviations from normal behavior are reported as anomalies and these can be used to generate alarms, or to show problem areas in live status dashboards or in reports. |

The Sensor Validator is part of Yanomaly's set of powerful industrial advanced analytics capabilities. To learn more about our AI-powered solution, click here. |

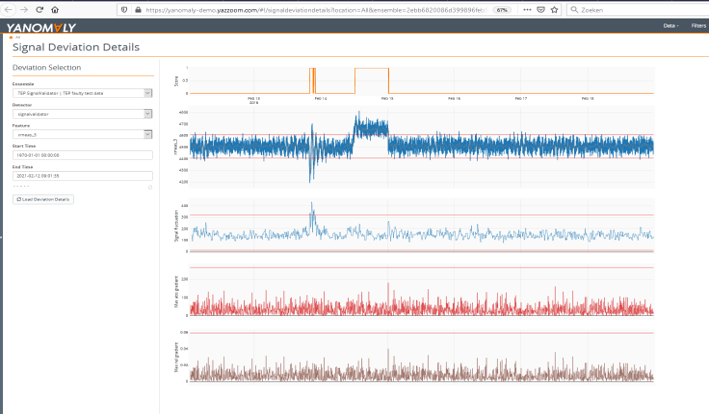

The web browser based graphical user interface as shown above allows an easy drill down to the detailed reasons for the occasional high anomaly score on a signal in order to facilitate the root cause analysis.

To configure Yanomaly to monitor thousands of signals at the same time is made easy and does not require data science or programmings skills.

To configure Yanomaly to monitor thousands of signals at the same time is made easy and does not require data science or programmings skills.