Modern plants and factories have hundreds or even thousands of PID and other control loops. Keeping track of the control performance can be challenging but undetected control issues often have a very significant impact on product quality, production efficiency & volume, maintenance costs and can even impose safety & environmental risks.

This is why we have developed a new module for Yanomaly: the Control Performance Degradation Detector (CPDD).

This is why we have developed a new module for Yanomaly: the Control Performance Degradation Detector (CPDD).

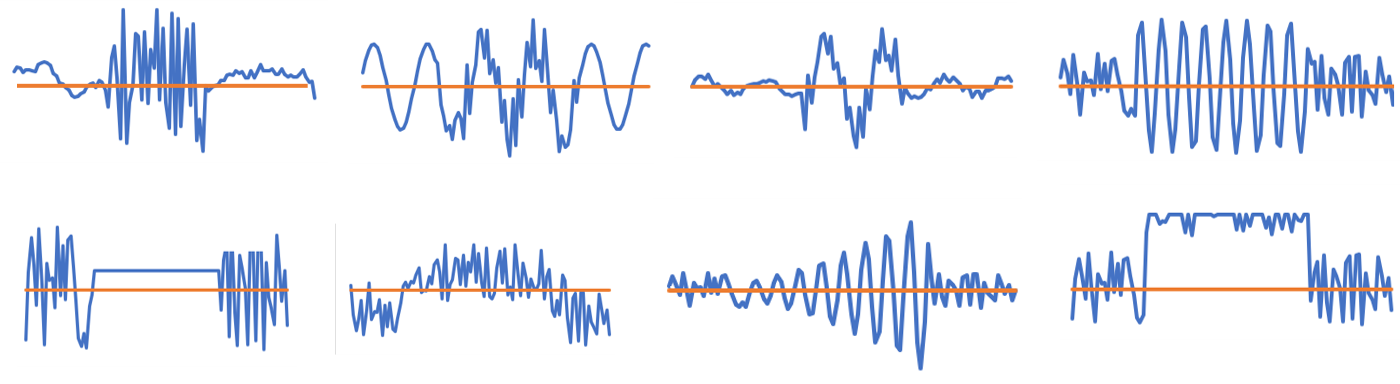

The CPDD detects degrading control performance of control loops and works with any (PID or other) controller.

Unlike CLPM (Control Loop Performance Monitoring) or CPA (Control Performance Analytics) tools, Yanomaly will not necessarily raise an alert or report an issue if a loop performs worse than some theoretical concept of ideal control. Instead it uses AI to learn for each control loop what the normal performance is, then only alerts if a control loop becomes worse. This avoids unnecessary alerts on control loops that always had a bit of oscillation or sluggishness because that was found acceptable or the best compromise.

Unlike CLPM (Control Loop Performance Monitoring) or CPA (Control Performance Analytics) tools, Yanomaly will not necessarily raise an alert or report an issue if a loop performs worse than some theoretical concept of ideal control. Instead it uses AI to learn for each control loop what the normal performance is, then only alerts if a control loop becomes worse. This avoids unnecessary alerts on control loops that always had a bit of oscillation or sluggishness because that was found acceptable or the best compromise.

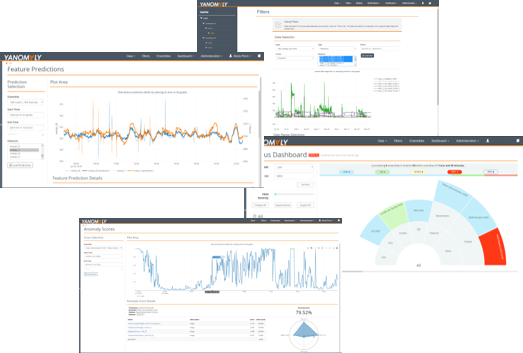

With its fast setup, auto-configuration for different loop dynamics and operating modes and its programming-free user interface, the CPDD delivers immediate value and retains Yanomaly’s flexible on-premise or in the cloud deployment and easy integration with any process data collection platform: OPC server, process data historian,…

It is sufficient that the CPDD has access to the trend data of the setpoint and process variable. If it also has access to the controller output and controller mode, it can detect even more control issues faster.

Yanomaly does not interfere with the control. It only reads and analyses the data and reports the results.

Results: Customers report that on average 5 important control or sensor or actuator issues are found per month, for on average one alert per day, per group of 300 control loops that are monitored by Yanomaly's CPDD. Investigating an alert only takes a few minutes because the CPDD is specific about the type of issue that it has found, and with one click the user sees the relevant trend plots in the user-interface for further investigation.

It is sufficient that the CPDD has access to the trend data of the setpoint and process variable. If it also has access to the controller output and controller mode, it can detect even more control issues faster.

Yanomaly does not interfere with the control. It only reads and analyses the data and reports the results.

Results: Customers report that on average 5 important control or sensor or actuator issues are found per month, for on average one alert per day, per group of 300 control loops that are monitored by Yanomaly's CPDD. Investigating an alert only takes a few minutes because the CPDD is specific about the type of issue that it has found, and with one click the user sees the relevant trend plots in the user-interface for further investigation.