| I'm so proud to announce that the Yazzoom team has won the 2024 Digital Innovation Award of the Belgian Maintenance Association with the novelties added to our Yanomaly software product for AI-supported data-driven maintenance and production optimization. The evaluation was made by a jury of 6 maintenance and asset management professionals from industry and academics. The jury was impressed by the demonstration of the latest additions for monitoring compressors, heat-exchangers and automated production lines, as well as with the broad applicability of the Yanomaly software for data-driven maintenance. Yanomaly can be added to any data collection platform or database of machine data, either on-premise or in the cloud, to bring sophisticated but yet easy to use AI-supported anomaly detection and predictive modelling. |

|

0 Comments

We are happy to report that Yanomaly is now available in several languages beyong English: Dutch, French, Finnish, German & Portuguese, with more coming soon!

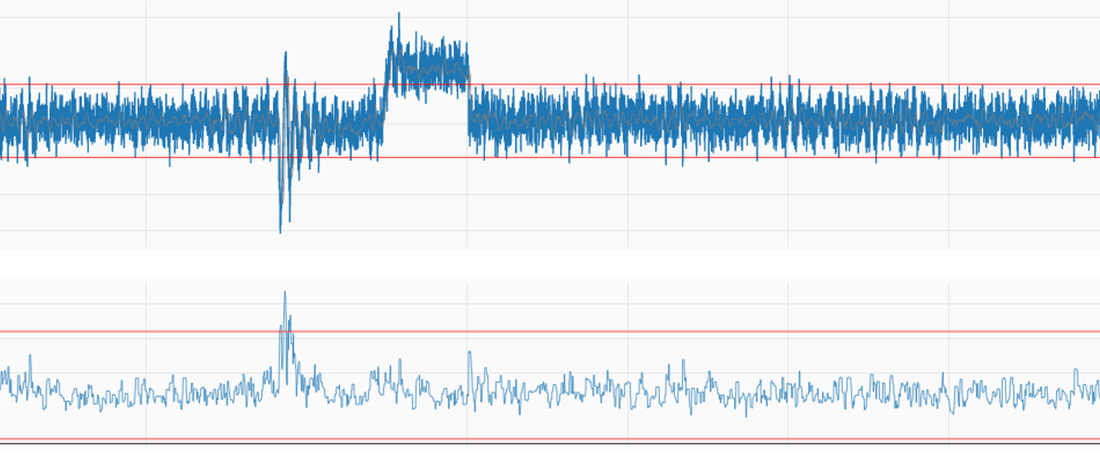

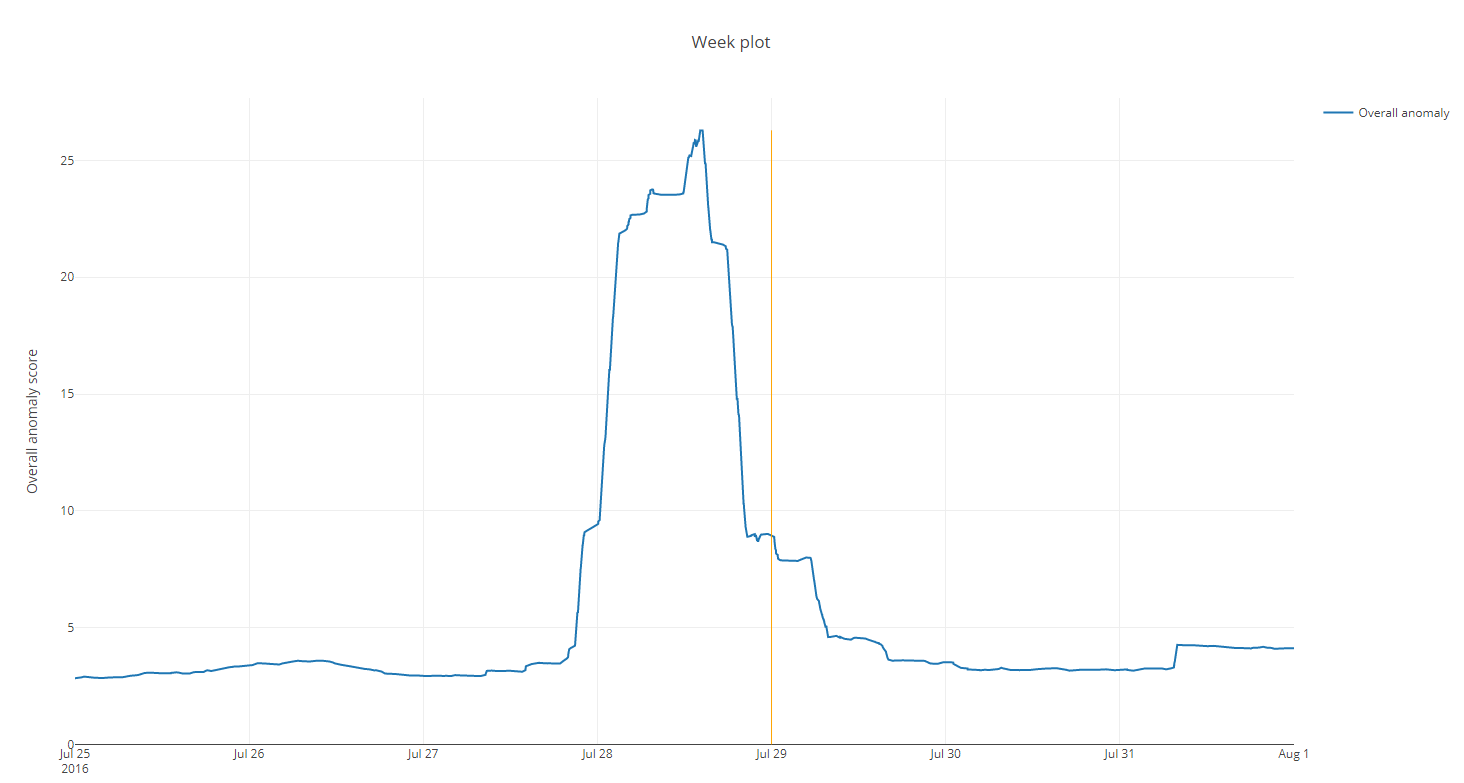

Installations are equipped with hundreds or even thousands of sensors. Yanomaly’s sensor validation automatically learns normal behavior of every individual sensor and reports abnormal ranges, abnormal dynamics, spikes and lost signals, while taking operating condition into account.

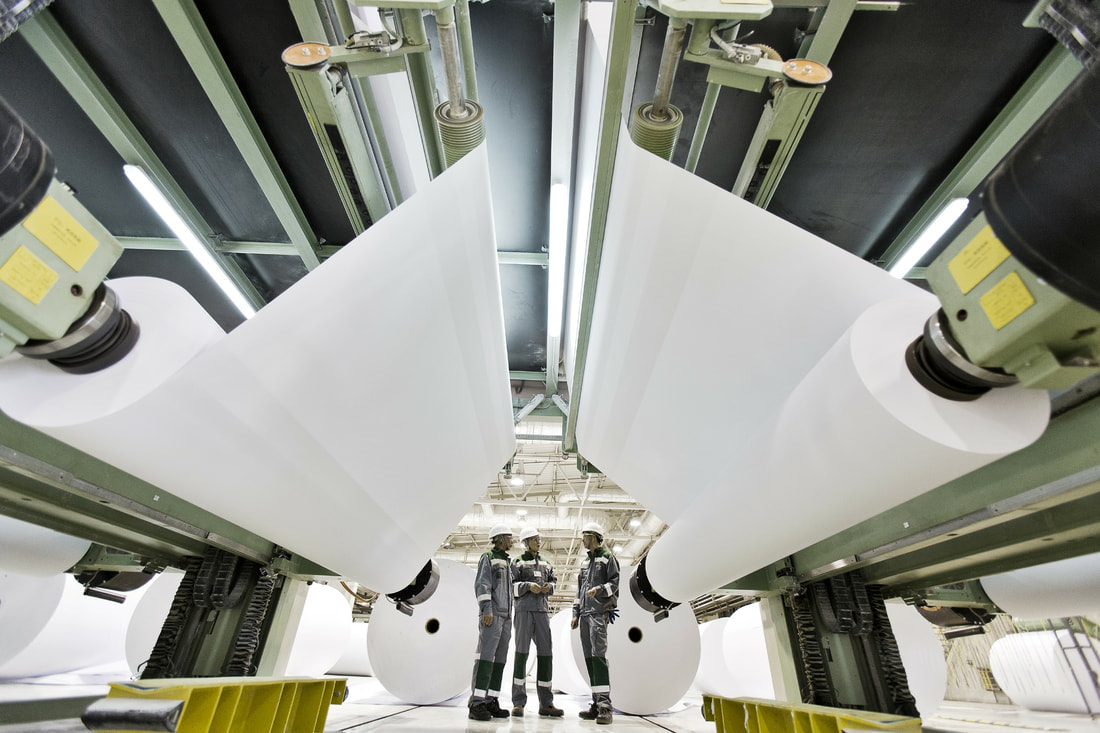

Our partner Tieto's upcoming Pulp Paper & Fiber virtual event. In the coming weeks, starting May 4th, you'll have the opportunity to attend webinars on the latest innovations and industry insights, network with industry experts, and more.

Modern plants and factories have hundreds or even thousands of PID and other control loops. Keeping track of the control performance can be challenging but undetected control issues often have a very significant impact on product quality, production efficiency & volume, maintenance costs and can even impose safety & environmental risks.

This is why we have developed a new module for Yanomaly: the Control Performance Degradation Detector (CPDD). Join us at the free Webinar "Hybrid Machine Learning for Smart Maintenance" on 25th March 2021 from 9 till 11 am for insights in leading edge data science technologies in the domain of industrial maintenance.

Thanks to three project grants, Yazzoom will be able to accelerate the development of its AI-powered industrial data analytics solution Yanomaly:

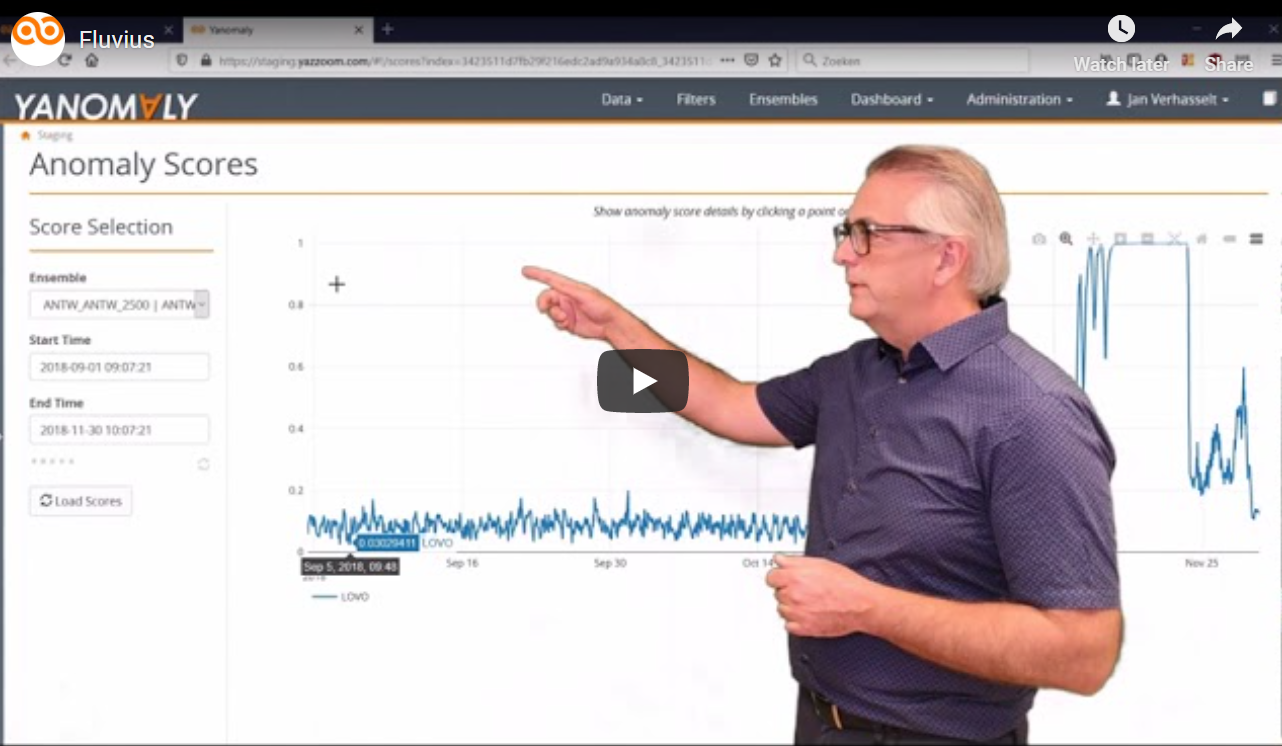

We are very proud to announce we are the winner of the Fluvius challenge to predict failures in electrical substations.

We ended up second (out of 13 contenders) in the Aquafin challenge to predict failures in pumping stations. In both cases we collaborated with domain experts to combine the best of Artificial Intelligence and Human Expertise: in the Fluvius case with Engie-Laborelec and in the Aquafin case with i-Care. If you haven't been able to follow the presentations during the conference, you can find the videos used in those presentations here. Follow the link to read about use cases for:

We are very proud to announce we are the winner of the Fluvius challenge to predict failures in electrical substations. We ended up second (out of 13 contenders) in the Aquafin challenge to predict failures in pumping stations.

In both cases we collaborated with domain experts to combine the best of Artificial Intelligence and Human Expertise: in the Fluvius case with Engie-Laborelec and in the Aquafin case with i-Care. If you haven't been able to follow the presentations during the conference, you can already find our video demonstrations of Yanomaly as featured during the competition by following this link. TietoEVRY and Yazzoom partnership promotes the use of Artificial Intelligence in the pulp, paper and fibre industry.

Data analysis in mills has a long history, but new technologies are making the next level possible through AI and machine learning. Yazzoom provides a rich set of tools and algorithms, from simple single sensor anomaly detection all the way to real-time predictive modelling and optimisation. TietoEVRY will embed these capabilities in its TIPS industry solutions and services. Click for more.  Asset monitoring systems based on artificial intelligence allow industries to reduce unplanned downtime, reduce mean time-to-repair, and increase the return on investment of maintenance operations in both the manufacturing and process industries. Download. In this project, 38 partners from six countries will be involved in research on the smart networking of development and production processes for electronic components and systems.

Development and production teams will be networked with each other, independent of their locations, and communicate in real time along the value chain. Processes can be virtually mapped by digital factory and product twins and can thus be simulated comprehensively. Artificial intelligence and machine learning play a central role in all of this. Read More. An article from our customer Water-Link, on the Proof of Concept project on the detection of anomalies in the water network of Antwerp.

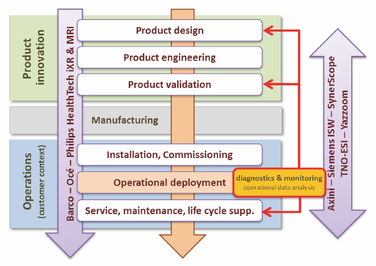

Read More. ITEA3 Reflexion Project "React to Effects Fast by Learning, Evaluation, and eXtracted InformatiON"5/9/2018 Reflexion will optimise the full end to end product development lifecycle and maintenance process, bringing in analytics to automate and complement expert knowledge, and enabling predictive maintenance on a broader industrial scale and shortening product evolution development iterations.

Read More.

|